Power tools

Audio for slide 2 (mp3 |6|KB)

Audio for slide 2 (mp3 |6|KB)

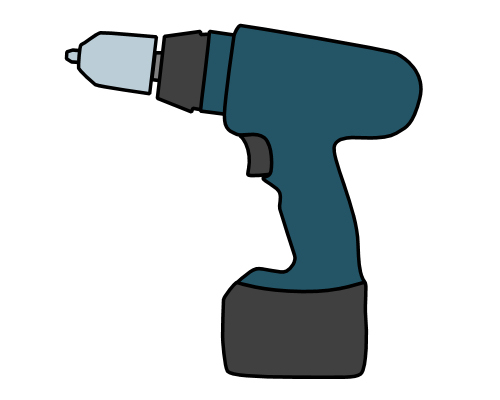

Nonetheless, most of these battery operated versions are not yet performing at a standard required by professional tradespeople - with the big exception of the variable speed drill.

Cordless drills are now used everywhere, because they are so light weight and convenient.

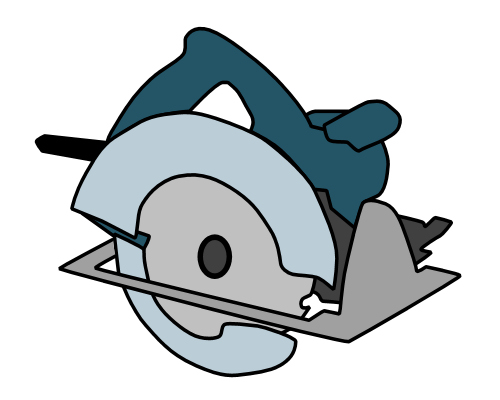

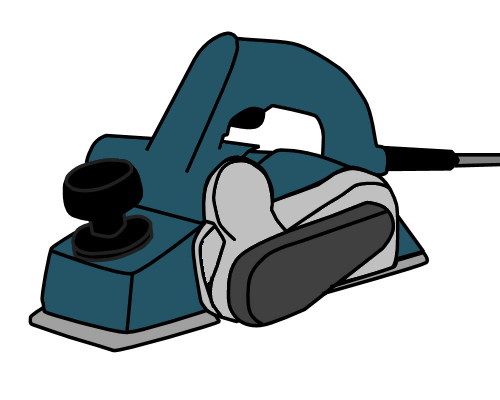

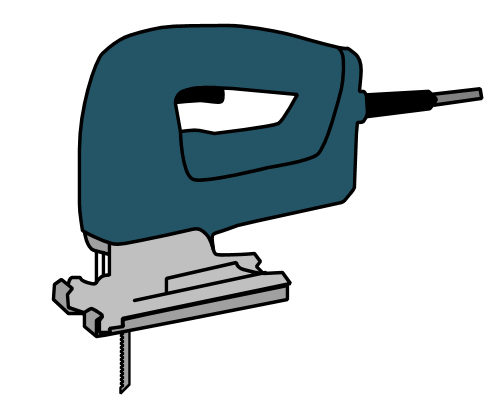

The tools described below all play a role in adjusting cabinets on-site, particularly when panels or bench tops need to be re-shaped or re-cut.

Audio for slide 4 (mp3 |6|KB)

Audio for slide 4 (mp3 |6|KB)

However, if you find that you've got no alternative to using a circular saw to re-cut a laminated board, the best advice is to:

- put the visible side of the board facing down while you're cutting so that the teeth cut upwards, which will reduce the chip-out on that side

- use a tungsten carbide tipped blade.

Audio for slide 9 (mp3 |6|KB)

Audio for slide 9 (mp3 |6|KB)

Drill

It's likely that you will take both 240 volt and cordless drills with you to the jobsite. The 240 volt drill will be used for the heavier work, such as drilling large holes or working with masonry. The cordless drill will do everything else, including drilling small holes and inserting chipboard screws.

Learning activity

Audio 11 (mp3 |6|KB)In the last two lessons we've looked at some of the most common hand and power tools used to make final adjustments to cabinets and components on-site. What have we missed?

Make up a list of any other tools you might need on-site to make adjustments or to re-shape panels prior to installation. Share your list with your trainer and other learners in your group.

Go to Safety with power tools

Go to Safety with power tools